The first must-have characteristic is the material must be smooth mixing. Materials which are difficult or chunky when mixed take more time and effort to completely mix which leads to unnecessary user fatigue by the end of an average workday. Additionally, smooth mixing tend to be easier to inject into the mouth as well. This provides greater control for operators which minimizes wastes by creating a more precise flow.

The second must-have characteristic of dental impression materials relates to how patients engage with them. Many lower quality materials carry a strong chemical or plastic smell which is off-putting to patients. Many people do not enjoy visiting their dentists anyway so any additional stressor, such as bad smells, can further lengthen the time between visits. The taste of the materials must be considered as well. Poor tasting materials can make it difficult for patients to sit still which can lead to inaccurate molds. An odorless, tasteless materials should be a high priority during the decision-making process.

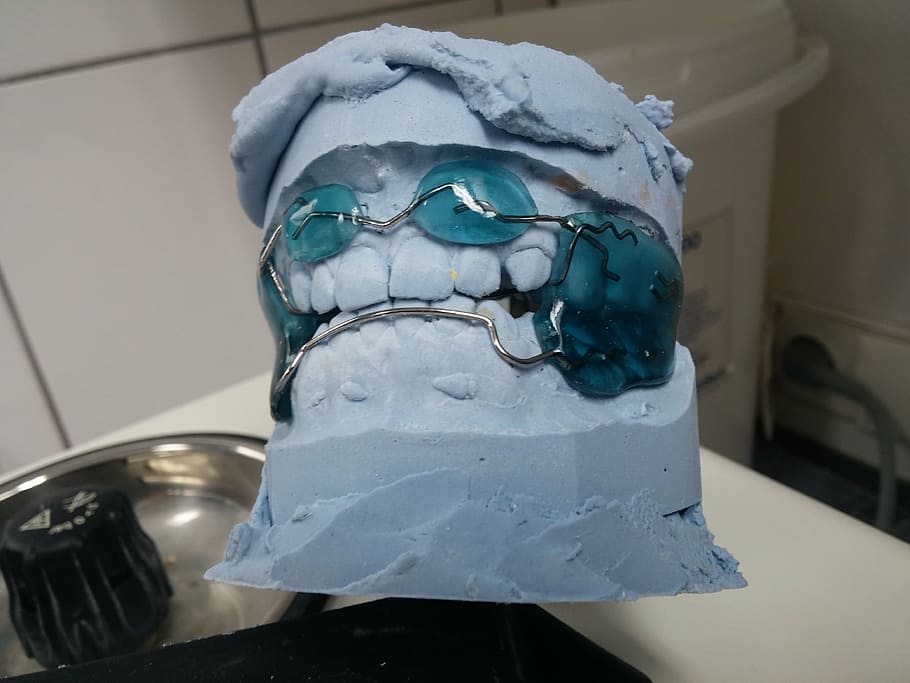

Another key factor to consider is elasticity prior to removal. Without high elasticity prior to removal dentists run the risk of both poor initial molds and damage to the mold during the removal process. High elasticity during removal combined with proper hardness following removal is essential. This is the only way to minimize negative deformation. Only the best dental impression materials offer the proper levels of hardness during all phases of creating and using the mold.

Dental impression materials must not only create a high-quality mold but the mold must be able to be used effectively. To ensure this, it is important the materials are conducive to detailed modeling with plaster. Generally, if the materials offer the proper level of hardness and detail it will be conducive to plaster as long as the materials do not stick to the plaster which can be caused by small chemical reactions.